Introduction

The Crossflow Cup’s objective is to provide competitive racing and share our love of vintage Formula Ford (FF) race cars. For the series to flourish, we need every competitor to follow the rules and specifications that allow us to race hard while maintaining respect and care for each other in completely legal, safe, period-correct cars that look great.

Vintage racing is a non contact sport. The Crossflow Cup encourages all competitors to race in a safe manner. It is the responsibility of each driver to ensure a safe race space for everyone involved.

Each race in the series is under the sanction of a host club. Acceptance to participate and enforcement of their rules is at the discretion of the host club. There are two areas The Crossflow Cup series and the host clubs take extremely seriously: safety and legality. We rely on high driving standards and thorough car preparation for the safety of everyone involved including workers, drivers and our vintage cars. Any penalties for a breach of the host club’s rules will be handled by the host club. This can include observation, probation, suspension or exclusion. Note that all the host clubs enforce strict no contact policy and may impose immediate exclusion from events for contact. The Crossflow Cup series provides input on driving standards and car legality issues directly to the host clubs. The Crossflow Cup series may also apply loss of points, trophies or grid place penalties. Any driver under suspension with the Vintage Motorsports Council (VMC) is not eligible for Crossflow Cup points or trophies during the period of the suspension.

Please review all the series rules and if in doubt at all, contact the series by email at crossflowcup@gmail.com. Also review the CSRG Club Rules and Driver’s Handbook on their website https://www.csrgracing.org. Specifically review the guidelines for safe passing. The Monoposto Rules are the worldwide specifications for Historic Competition used by the FIA, our sister clubs all over the US, UK, AU, CA, NZ and our local clubs like CSRG, SVRA, HMSA, RMVR. VARA, HRG, SVRA, The Royale Series, SOVREN, and more. Adhering to these well known and well established specifications allows acceptance by both the sanctioning club(s) as well as the Crossflow Cup series. Any variations or series specific rules are provided below.

The Crossflow Cup series will only thrive if everyone takes Safety and Legality seriously. Safety in the form of cars that have been carefully maintained, inspected regularly (including crack tests), have up to date safety and fire systems and do not leak fluids. Safety also in the form of cars with brake and suspension settings that keep them stable and easy to drive. Legality in terms of engines that make no more than the 114-115 horsepower of a legal Kent motor.

Series Rules and Race Format

Racing in Formula Fords tends to be more intense than some of the other vintage classes. This does not mean you can ignore the basics that keep us all safe. It is still vintage racing.

Each host club's rules are in force for each event. Be sure to review them carefully. If there are any variations, we will outline them in pre-race communications and at the Driver’s Meeting.

Vintage racing is a non contact sport. Any penalties for contact will be handled by the host clubs. The Crossflow Cup series works closely with the host clubs to support their decisions and actions.

Car Preparation

Safe, well prepared cars are mandatory.

The host club’s tech will certify the car is safe and competition ready. Car compliance is handled by the Crossflow Cup Steward, who upon application will issue a compliance sticker certifying that the car is not in violation of the class specifications. Occasionally the Crossflow Cup series will issue tech and safety bulletins for key issues or common problems. Competitors will have one race weekend to comply with the bulletin if needed. Crossflow Cup has no formal protest procedure. We encourage any competitor who feels that another competitor’s car may not be legal to notify our steward as soon as possible. We would much rather get in front of a problem than have to sort out a rule violation after the race. Just because we have no SCCA type formal protest procedure doesn't mean we turn a blind eye to cheating. The series will continue to inspect cars post race, even those that have a compliance sticker.

All cars will be period correct and presentable. Cars with below standard paint, graphics and other cosmetics, will have one year to remediate if directed to do so by the series or host club.

Driver’s names, graphics, period correct advertising is encouraged, but note, may violate local club host rules.

We do not allow engines built by Pick’s Racing Engines. If you have an engine that was built there, it must be inspected and certified by a “known” builder. This is handled on a case-by-case basis. If you have any questions about how to make sure your engine is legal, reach out to us before signing up for an event.

The use of video Cameras is strongly encouraged.

Data collection is allowed. We ask that if a data system is to be in use, its installation is hidden to maintain a period correct appearance. That is, we would like to see gauges in all cars rather than digital displays. This applies to onboard lap timers as well. Please try to avoid mounting them in a terribly conspicuous place like the steering wheel.

Remember, what is MOST important is the “esprit de corps” in our paddock. Approach this like Goodwood or the Civil War reenactment folks. We are all here because we love vintage Formula Fords. Let’s remember that when the visor goes down.

Steward’s Competition Guidelines - High Driving Standards

This group thrives when everyone maintains a vintage racing attitude. The primary focus is on safety. Beating your friends in a fair fight or becoming a better driver/athlete should be a secondary focus. There is no room for a “win at all costs” mind set. We are here to have fun, share, learn, and develop. That means you need to drive so that people are excited to see you in the paddock and at the party. You should be able to look every athlete/driver in the eye and feel good about your performance. Most of what follows are “Gentlemen’s Rules”. Remember, we are all supposed to be gentlemen/gentlewomen, let's act accordingly.

Drivers Meetings

The Crossflow Cup will have a drivers meeting immediately following the host club’s drivers meeting. Attendance is mandatory and roll will be taken. Failure to attend the Crossflow Cup drivers meeting can result in penalties including: a warning, loss of grid position, and/or loss of points.

Driving Etiquette

Take care of the new drivers - We have new people stepping into a race car for the first time at most races. Help and support them. That is how we keep the party fun and growing!

Fast guys have no extra rights - Just because you are fast, does not entitle you to anything. In fact, it puts the burden of care on you for the majority of the grid who run at more moderate speeds.

Avoid spins - We have large grids, so losing it in front of a bunch of cars can really suck. Brake with the steering straight; ease on the throttle once your hands open back up; keep your vision up; hit your marks.

Passing - Keeping momentum up is the obsessive focus of every Formula Ford driver. This however, can lead to the ill-judged pass... a leading cause of angst and damage. Please read the guidelines for passing in the CSRG Driver’s Handbook. Basically, if you are not next to the car in front, prior to the turn-in zone (you should know where that is), you're not going to make it cleanly. Amateurs (and pros sometimes) often commit to passes from way too far back expecting to be seen, even if that means the driver in front would need to dislocate his/her neck to look back.

Passing in an ill-judged spot - For example, the inside of turn 6 or the inside of turn 9 at Laguna; these are NOT good places to attempt a pass. If it is a late pass, it will have consequences. We operate by the 90/10 rule when it comes to passing. It is 90% incumbent upon the overtaking car to complete a safe pass, but 10% of the responsibility of the car being overtaken to concede when the pass is all but done. Remember, we all have to be friends at the end of the day. Which leads us to our next point:

Squeezing - Pressuring the car next to you, by leaving no room or only poor choices... is NOT okay in this series. If the car next to you only has the choice of backing out of the throttle, hitting the wall, or going off track, you are not in the right zone. Leave room to the left between you and the wall at all times. And if you go into a corner side by side and you are on the outside, the guy on the inside is more loaded up and less able to predict grip... so leave space, you might both need the room.

Yellow Flags

For all Crossflow Cup sessions, the out lap is to be considered Full Course Yellow, whether the workers display it or not. This is for all sessions: practice, qualifying and race. This is due to numerous issues in the past. Please don’t consider the out lap a parade lap, keep your speed up, warm your tires and brakes, assess track condition then be prepared to go as soon as you pass start finish. Just don’t pass until then.

The Yellow Flag no passing zone starts when you can see the yellow flag and continues past the incident until you can see the next staffed flag station not displaying a yellow flag. You do not have to reach that station, it just needs to be in view. This practice is more conservative than other groups use, but we do it in the spirit of safety. If you make a pass under a yellow and realize it, give the position back. Failure to follow the Yellow flag procedure can result in series penalties up to and including: a warning, loss of grid position, or loss of points. It can also lead to exclusion from the event by the host club. Communicate properly - If you see a yellow, put your hand up and communicate with those around you.

Racing during qualifying - We want a clean grid based on true lap times. Do not impede each other or compete with protective lines during Qualifying. The goal of qualifying is to do your best and let everyone's true speed set the grid.

Messy racing - Jumped starts, excessively fast starts, missed flags.... all lead to cars getting lapped too early in the event and the group looking bad. When possible, a Start Judge will be posted in the starters box for each race. It is the Start Judge’s decision and his/her decision alone if a jumped start attempt has been made. Immediate punishment will follow.

WHAT IS A JUMPED START? - good question. When the grid is formed up, we want ONE SPEED to be held until the green flag is waved. Drivers are allowed to look left or right, but competitors should not accelerate or decelerate once that speed is reached until the green flag is waved. This rule is intended not only to eliminate jumped starts, it is also to eliminate contact due to accordion effect. This rule applies to the pole sitter as well. The penalty for a jumped start is a stop and go in pit lane, to be served IMMEDIATELY or the driver will be disqualified from the race. No exceptions. The Start Judge’s rule is final and unappealable.

Grid Procedures

A typical Crossflow Cup schedule will have a Qualify session and Race on Saturday. Then a second Qualifying session and Race on Sunday. Cars will be gridded for the first qualifier based on the best lap time from Friday's final practice sessions. Cars will be gridded for the second qualifier based on the finishing order from the first race. If there is no Friday test day, or in the event of major timing and scoring breakdown, the grid will be set by the board taking into consideration the current points standing and known previous lap times. Remember that ultimately grid control is handled by the Host Clubs, please always flow the direction of the Grid Officials.

Car Class Specifications

The Crossflow Cup series follows the Monoposto Rules for Historic Formula Ford (HF) and Club Formula Ford (CF) and the National Vintage Formula Ford Association Rules and Regulations with only a few minor changes, notably Tires and Minimum Weight. These are the worldwide rules for Historic Competition used by the FIA, our sister clubs all over the US, UK, AU, CA, NZ and local clubs like CSRG, SVRA, HMSA, RMVR. VARA, HRG, SVRA, The Royale Series, SOVREN, and more. Adhering to these well known and established specifications allows acceptance by both the sanctioning club(s) as well as the Crossflow Cup series. The following are consolidated specifications where HF and/or CF exceptions and clarifications are noted within each section.

Definition

A class for single seat, open wheel race cars raced by private owners, using the standard Ford 1600 crossflow, pushrod engine.

Pre-1973 Historic Formula Ford (HF)

The following commercially constructed cars are eligible:

Alexis 14 [1968] 15 [1969] 18 [1970] 18B [1971] 22 [1972]

Beach MK11 [1969-70]

Bobsy [1969]

Caldwell D9 [1969] D9B [1970-71]

Crossle 16F [1968-69] 20F [1971-72]

Dulon LD4 [1967] LD4B [1968] LD4C [1969] LD9 [1970-72]

Elden PH6 [1969] PH8 [1970-72] PH10 [1972]

Elfin 600 [1969-72]

Forsgrini MK12 [1968-69]

Ginetta G-18 [1969-70], G-18B [1971]

Hawke DL2 [1969] DL2A [1970] DL2B [1971] DL9 [1972] DL9A [1972]

Le Grand MK10 [1969-72]

Lola T200 [1970] T202 [1971] T204 [1972]

Lotus 31 [1967] 51 [1967] 51B [1968] 51C [1969] 61M [1970-72] 61MX

Lynx Formula Ford [1970] [1972] 69 [1971-72]

Macon MR7B [1969] MR8 [1969-70] MR8B [1971]

March 709 [1970] 719 [1971] 729 [1972]

McNamara FFA [1970]

Merlyn MK11 [1968] MK11A [1969] MK17 [1970] MK17A [1971] MK20 [1971] MK20A [1972]

Mirage MK5 [1970]

Mistrale [1969-70]

Nike MK4 [1968-69] MK6 [1970] MK10 [1971-72]

Royale RP2 [1969] RP3 [1970] RP3A [1971-72] RP16 [1972]

Tecno FF [1970]

Titan MK4 [1969] MK5 [1969] MK6 [1970] MK6 - all

Winkleman WDF1 [1969] WDF2 [1970] WDF3 [1971] WDF4 [1972]

1973-1981 Club Formula Ford (CF)

The following commercially constructed cars are eligible:

ADF – Mk II

Alexis – MK23/24/24B

Caldwell – DL15FF and DL9 made in 1975

Crossle – 25F/30F/32F/35F/40F/45F

Dulon – MP15/17/19/21

Eagle – DGF

Elden – PRH10/17/19/20, HD24

Elfin -620

Hawke – DL11/12/15/17/19

Hermes – 16/79, 16/80

Huron – FP2 HR2760

Gemini - 1981

Image – FF2/2B/3/4/5

Javelin – JL2/5

Legrand – MK13/13B/21/27

Lola – T340/342/440/540

Merlyn – MK24/25/28/29/30/31

PRS – RH02, 81F

Reynard – 73F/76F/77F/78F

Rostron – RT 77/78

Rowland – 1975/76 RP, RP 24-77, RP26-78

Royale RP21/24/26/31* (case by case basis for RP31model)

Sark 2

Sparton – FF78

Titan – MK8/9

Tiga – FF75F/76F

Van Diemen – RF 73/74/75/76/77/78/79/80/81

Viking – None

Winkleman (became Nomad–Palliser) – KHF/1 (WDF4), KHF/2 (WDF5/6)

Zink – Z-10, Z-16

Zeus – FF81

Any otherwise eligible Formula Ford not on the Crossflow Cup Eligibility List may be considered for eligibility upon application to Crossflow Cup by the car owner.

II. ENGINE

Detailed engine rules are included in separate sections below. In short, they are the 2026 National Formula Ford Association Rules and Regulations Kent and Cortina engine rules.

III. TRANSMISSION

Any transmission may be used with not more than four forward speeds and an operational reverse. Gearing selection is free.

IV. FINAL DRIVE

Any final drive may be used except:

a. drive shall be to the rear wheels only;

b. limited slip and locked differentials are prohibited;

c. alloy differential housings are frowned upon, but allowed.

V. CLUTCH

The use of any single plate clutch is permitted provided no modification is made to the flywheel other than changing the points of attachment of the clutch to the flywheel. Flywheel may be modified to accept a single plate sintered metallic clutch [e.g., AP Borg and Beck, Tilton, etc.] providing no other regulations are broken. Carbon fiber clutches are not permitted.

VI. CHASSIS

The chassis shall be of tubular steel construction with no stress bearing panels except the undertray and a single transverse bulkhead. The curvature of the undertray shall not exceed one inch. The tubes may be used to transport liquid [oil or water] unless specifically prohibited by current general competition rules in the region. Monocoque construction is prohibited. With the exception of safety related tubing [6" maximum length], no modifications from the original are allowed.

Crossflow Cup Clarification:

Monoposto wording from HF and CF have been combined but not altered.

VII. SUSPENSION AND RUNNING GEAR

All components shall be of steel with the exception of hub adaptors, rear hub carriers, bearings and bushings. Wheel spacers shall not exceed 2" (Monoposto specification is 1.5”). Shock absorbers are free except that they shall not be more than two-way adjustable and shall not have remote reservoirs. Aluminum shock bodies are allowed.

HF Specification:

Rubber donuts must be retained on rear half-shafts unless the car owner can prove that constant velocity [CV] joints were used on the car originally. All historic Formula Fords must use donuts in the driveline except for those specific cars that have demonstrated their use in their racing design and history and have received exemption from the Crossflow Cup board.

CF Specification:

CV joints are permitted. At a minimum, one end of the car shall have outboard suspension.

VIII. BODY

No part of the frame or body shall project beyond a plane connecting the vertical centerlines of the front and rear tires. Detailed exhaust requirements are spelled out in the engine specification section.

The driver's seat must be capable of being entered without the removal or manipulation of any part or panel.

Wings [airfoils] are prohibited.

Crossflow Cup Clarification:

Monoposto wording from HF and CF have been combined but not altered.

IX. BRAKES

Free, except the restriction to cast iron calipers and iron discs.

HF Specification:

The addition of cockpit adjustable brakes bias systems is frowned upon, as not period correct, but allowed.

CF Specification:

Cockpit brake bias adjusters are permitted.

X. WHEELS

Wheels shall be either 13" pressed steel disc type with a maximum width of 5.5" or alloy of same dimension. Offset is free, as is bolt spacing. Centerlock wheels are not allowed.

XI. TIRES

Crossflow Cup tire specifications will be updated based on tire availability. Currently the Avon (A46 compound) and Hoosier VFF are allowed. The specific tires allowed are:

Front:

Avon 5.0/22.0-12 A46 17680

Hoosier VFF 44165, 135/545-13

Rear:

Avon 6.5/23.0-13 A46 17681

Hoosier VFF 44170, 165/580-13

It is not permitted to mix the tire brands

Additional grooving or hand-cutting is not allowed.

Rain tires are not allowed.

Using multiple sets of new tires per weekend is not allowed.

XII. MINIMUM WEIGHT

HF Specification:

The minimum weight is: 1100 lbs [as qualified or raced with driver].

CF Specification:

The minimum weight is 1125 lbs [as qualified or raced with driver].

XIII. FUEL TANKS

All fuel tanks must be properly secured. The original elastic cords are in most cases inadequate. Fuel cells are required. They must be of a type approved by CASC, SCCA, FIA, IMSA, etc. for road racing. Tanks must be in the original location or, if relocated, be entirely within the chassis frame.

XIV. ORIGINAL SPECIFICATIONS

All cars must compete in the identical specification as manufactured and raced. Updates and modifications, however "period" they might appear, are specifically prohibited. Relocation of suspension pickup points, alteration of wheelbase or track are examples of prohibited modifications. All body panels originally supplied with the model, with the exception of the engine undertray, must be used. They must be the original shape. The car must be restored to the original period specs, unless otherwise approved in writing. Updates and modifications which were made during the life of the car to improve its competitiveness and safety are permitted. However, the racer, if challenged, must be able to demonstrate that these changes were in compliance with the rules in effect during its racing history.

XV. PRESENTATION

All cars shall be presented with a clean and finished appearance in keeping with the spirit of vintage racing.

Engine Specification

Kent Engine

a. General

1. Components shall not be interchanged between the Kent and Cortina versions of the engine unless specifically authorized.

2. The engine shall not be altered, modified, or changed in any respect unless specifically authorized herein. When a system is specified to be “unrestricted”, the restrictions of this paragraph do not apply.

3. The gasket face of the cylinder head may be resurfaced provided the maximum compression ratio is not exceeded.

4. Valve guides are unrestricted provided the position of the valve is not changed. Standard Ford replacement valves, with oversize stems, may be used as normal repair/maintenance procedures. The specifications in paragraph 1.f (valves), are mandatory. It is permitted to re-cut or replace valve seats. Valve seat angles in the head are unrestricted.

5. Exhaust emission control, air pumps, and associated lines and nozzles shall be completely removed. When these air nozzles are removed from a cylinder head, the holes shall be completely plugged.

6. Balancing of all moving parts of the engine is permitted. The pistons, rods, crankshaft, and flywheel may be lightened to their stated minimum weights. It is permitted to polish parts of the engine providing the contour of the part is not altered and can be recognized as the original part. REM Polishing is allowed. Cryogenic treatment of parts is allowed. Pistons may be balanced to the minimum weight by removing weight from the pin boss, the underside of the piston crown, or the bottom edge of the skirt. “Gas porting”, re-profiling, or any other modification to the piston, other than expressly permitted herein, is prohibited. Addition of coatings ( anti-friction, thermal, etc.) to internal engine parts is prohibited unless the part is listed as unrestricted herein. Knife-edging the crankshaft throws is not permitted.

7. Compression Ratio

Maximum compression ratio: 9.3 to 1

The following specifications are used in determining compression ratio:

A. Maximum bore size: 3.200”

B. Minimum cylinder volume at Top Dead Center: 42.0cc

C. Maximum valve protrusion from head surface: .040”

D. Only approved head gaskets may be used (see 1.c.4 )

The following methodology and values shall be utilized to determine compression ratio (CR)

CR = (Swept Volume + Unswept Volume) / Unswept Volume

Swept Volume (cc) = (3.1416/4) * (measured bore dia } * (measured bore dia) * (measured stroke) * 16.387

Unswept Volume = top of piston to top of block + top of ring to top of piston + head gasket - valve/plug protrusion in head

Top of piston to top of block (@TDC) = measured value by fluid cc’ing. (42.0cc minimum)

Top of ring to top of piston = fixed value 1.33cc (regardless of piston machining)

Head gasket (cc) = (3.1416/4) * (measured diameter) * (measured diameter) * (measured compressed thickness) * 16.387

Valve/plug protrusion = fixed value (0.4cc) regardless of actual valve configuration.

b. Block

1. Use of Ford engine block P/N 711M-6015B-A (uprated) is required. Alternatives listed below are allowed

2. Bore may be enlarged for clearance between cylinder and piston.

3. Cylinder sleeves may be fitted. The top surface of the block may be milled or surface ground to obtain the maximum compression ratio specified above. Any steel center main bearing cap may be used. The oil pump mounting face on the block may be machined for the purpose of fitting an oil pump.

4. The 1600 Fiesta block is permitted as a replacement part. Ford P/N 681-F6015D-A

5. The Ford Racing block, part number M-6010-16K, is permitted as a replacement part.

6. Block may be clearanced for fitting an alternate crankshaft allowed by these rules.

c. Cylinder Head

1. Use of the Ford 1600 cast iron cylinder head (casting 2737E) is required. Alternatives listed below are allowed.

2. Ports may be reshaped by the removal of metal as long as the port diameter at the manifold face of the head does not exceed the following dimensions:

Inlet: 1.50”

Exhaust: 1.20”

3. The use of the Pierce aluminum cylinder or Ivey Engines P/N 1.6XFCH aluminum cylinder is head is permitted.

4. The following head gaskets are allowed:

A. Ford Part # 931M6051AA

B. Payen Part # AH-750

C. Felpro Part # 8360PT-1

D. Victor-Reinz 61-24405-20

d. Inlet Manifold

1. Use of Ford intake manifold P/N 711F-9424-HB/HC (uprated) is required

2. The ports may be reshaped by the removal of metal as long as the following dimensions are maintained:

Maximum dimension at head face: 1.340”

3. Carburetor Flange

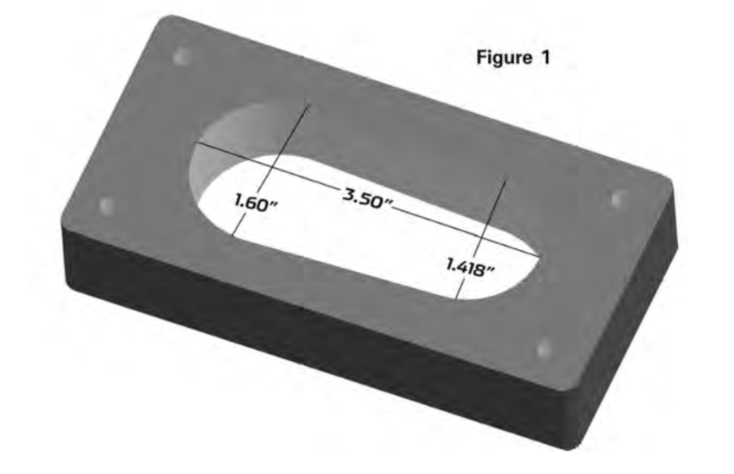

Maximum dimensions at carburetor flange: see Figure 1.

3. The carburetor face of the inlet manifold may be machined to the horizontal to compensate for fore/aft tilt of the carburetor.

4. Epoxy exposed in the manifold used to make repairs is acceptable, providing the total area is less than 0.75 square inches.

5. The water passages in the inlet manifold may be plugged. Holes in the inlet manifold resulting from the removal of emission/vacuum lines shall be plugged.

e. Pistons

1. Use of Ford cast pistons (casting 711M-6110) are required. Alternatives listed below are allowed.

2. Standard or 0.005 inch oversize pistons shall be used.

3. Standard size AE pistons P/N 18649, casting P/N 18634, standard size CP piston, part # 81 -2 FF1600, or CP oversize piston, part # 81-2- FF1600+5 may be used.CP pistons supplied after 1/1/2010 must bear the Ivey logo

4. Alternate piston identified as follows is allowed: P/N AE-M717D, casting number 711 M 6110. AE Hepolite P/N 20552, Casting # 20548A. Note: Mahle pistons are not allowed.

5. Dimensions and Weights

Maximum diameter: 3.187”

Standard: 3.192”

0.005” o/s:

Depth of bowl: 0.470” (minimum)

Maximum diameter of bowl: 2.44” AE Hepolite,

2.50” CP Piston

Centerline of wrist pin to crown: 1.702” +/- .002”

Overall height: 3.30” AE Hepolite

2.80” CP Piston

Minimum weight: 515 grams (w/ clips, pins and rings)

Weight of pin: 115 +/- 2 grams

Ring Groove Widths: Top Groove: 0.064”

2nd Groove: 0.0795”

Oil Groove: 0.159”

6. Piston rings are unrestricted provided that:

A. One oil control and two compression rings are used.

B. No modification is made to the piston for the installation of rings.

C. Pocketing of the piston valve reliefs is allowed up to a maximum of .050” to achieve legal compression ratio.

D. Piston top rim may be machined to reduce bowl depth (0.470" minimum) as required to achieve legal compression ratio. Acceptable to break sharp edges of machined area (0.015 x 45 deg max)

E. Removal of material from the piston bowl area is not allowed.

7. Wrist Pins are unrestricted provided that:

A. Weight is 115 +/- 2 grams.

B. No modification is made to the piston for the installation of the wrist pins.

f. Valves

1. Use of Ford intake and exhaust cylinder head valves P/N DORY-6507A or 2737E-6507-G (Intake) and DORY-6505-D (exhaust) are required. Alternatives listed below that are of the same material, profile, and finish, remaining essentially identical to the original Ford valves are allowed.

2. Dimensions Distance apart at centers

Iron head Alloy head

Distance apart at centers 1.540” +/- .020” 1.570” +/- .020”

Max. diameter: Inlet: 1.560"

Exhaust: 1.340"

Overall length:

Inlet: 4.367" +/- .020"

Exhaust: 4.355" +/- .020"

3. Reshaping of the valves is specifically prohibited.Grinding or lapping valve face is allowed,provided 45 degree face angle and all profile details remain unchanged. Back cutting of valve is strictly prohibited.

4. Alternate valve AE p/n V34524 (intake), V34525 (exhaust), as well as Ford

reproduction valves p/n 13248 (intake), 13249 (exhaust) as supplied by

Ivey Engines are permitted. Valves must bear P/N or OEM logo.

g. Camshaft

1. Use of Ford camshaft P/N 701M-6250-BA is required. Alternatives below are allowed.

2. Regrinding camshaft lobes is permitted, providing they are ground to meet FORD and SCCA profile.

3. Camshaft Lobe Centers: 109° +/- 2°

Lift at top of pushrod:

Inlet: 0.231” +/- .002” Maximum

Exhaust: 0.232” +/-.002” Maximum

Lift at spring cap: (Valve Lift)

Inlet: 0.356” Maximum

(Zero tappet setting)

Exhaust: 0.358” Maximum

4. Recontouring of the valve stem contact pad of the rocker arm is permitted, provided the maximum lift at the spring cap is not exceeded

5. Offset camshaft/sprocket dowels are permitted.

6. Camshaft profile and lobe centers shall be checked using the official procedure published by NVFFA and SCCA.

7. A camshaft that is a replica of the original camshaft and of the same material may be used.

h. Valve Springs

Valve springs and valve spring shims are unrestricted, except that:

1. Springs and shims shall be made of steel.

2. No more than one spring shall be used per valve.

3. Conically wound springs are not allowed.

4. The standard spring cap and retainers shall be used.

i. Pushrods

Minimum stem diameter: 0.25"

Overall length: 7.64" Minimum

Minimum weight: 50 grams

j. Connecting Rods

Any ferrous connecting rod may be used provided it meets a minimum weight of 630 grams and has a center-to-center length of 4.925 +/- 0.020 inches.(Oversize / offset small end bushing may be utilized to adjust rod length within tolerance stated above) (Note: Weights include cap, bolts, and small end bush, but not big end bearing shells).

k. Crankshaft

An alternate cast steel crankshaft meeting original Ford Kent and SCCA dimensions and weight is permitted.

Weight: 24 lbs. 8 oz. Minimum

Max Stroke (at piston): 3.056” +/- .004”

Crankshaft pulley: unrestricted

The crankshaft from the Cortina engine may be used.

The crankshaft from the Fiesta engine may be used.

The crankshaft may be shot-peened.

Note: Minimal localized clearancing of block for crankshaft clearance is permitted

l. Flywheel

1. Use of Ford 1600 flywheel is required. Alternatives listed below are allowed.

2. Weight with ring gear: 15.5 lbs minimum.

3. The flywheel may be machined to reduce weight to the above minimum weight. Flywheel locating dowels are permitted.

4. Weight may be added to the flywheel, providing it is added ONLY to the existing clutch bolt holes, i.e., single cap screws or set screws. No continuous material shall be used.

5. An alternate flywheel, part # JAE1600 is also allowed at the above weight of 15.5 lbs.

m. Carburetor

Weber 32/36 DGV or Holley 5200

Venturi diameter: Primary: 26mm

Secondary: 27mm

It is permitted to:

1. Fit any jets (including accelerator pump discharge nozzle) as long as no modifications to the carburetor body are required.

2. Modify or substitute the external throttle linkage.

3. Fit internal and/or external surge pipes.

4. Remove the air cleaner

5. Fit velocity stacks

6. Remove the choke butterflies and linkage.

7. Use an alternate carburetor to intake manifold gasket/ spacer provided the total thickness does not exceed 0.025" and doesn’t exceed the manifold opening dimensions

8. Modify the carburetor housing for the installation of throttle shaft bearings provided the modification serves no other purpose.

n. Fuel Pump

Unrestricted

o. Exhaust Manifold

Unrestricted

p. Lubrication System

Lubrication system is unrestricted; any oil pump and oil sump permitted, providing it is gear driven off the camshaft (no belt drive pumps). Localized machining of the cylinder block is permitted to allow fitting of the oil pump. Dry sump system is permitted.

q. Cooling System

Cooling system is unrestricted. Any radiator, fan, water pump and drive belt permitted. Pump/fan/generator drive belt: Unrestricted Remote mounted water pumps ( electrical or Belt driven ) are not permitted.

r. Electrical Equipment

Distributor: Distributors are unrestricted provided the original drive, location, and housing type are retained. Electronic trigger devices may be used with any distributor (in lieu of mechanical points). The distributor is defined as the component that triggers the LT current and distributes the HT current. The ignition timing may only be varied by vacuum and/or mechanical means. It is prohibited to use any other method or component to trigger, distribute, or time the ignition (e.g. Multi spark, spark amplifiers, crank triggers, capacitive discharge systems are prohibited). The vacuum advance mechanism may be removed, and the distributor advance plate may be secured by soldering or welding or by suitable fasteners. The advance curve and advance springs are unrestricted. Generators/ Alternators: not required. All other electrical components are unrestricted.

s. Miscellaneous

1. The timing chain/sprocket cover may be altered or replaced.

2. The use of the following non-standard replacement parts is permitted provided their use does not result in any unauthorized modification of any other component:

A. Fasteners - nuts, bolts, screws, studs, etc. Intake manifold fasteners may be of either a socket head or hex head configuration, and must be 5/16” diameter.

B. Gaskets, except head gasket, Carburetor to inlet manifold and inlet manifold to cylinder head gasket is specified in these rules .

C. Washers.

D. Seals.

E. Connecting rod, crankshaft, and camshaft bearings of the same size and type as original. Normal oversize/undersize bearings are permitted. This does not allow reducing the bearing surface area by reducing the width of standard bearings.

F. Spark plugs. Restricted to the standard 3/4” reach spark plugs. (14mm thread, 0.80” max reach)

G. Rocker pedestals that are of the same material and dimensionally identical (i.e., shaft location, offset, etc.) to the original components may be used.

3. Mechanical tachometer drive is permitted.

4. The crankcase breather may be altered or removed.

5. The standard rocker cover may be altered to provide for crankcase ventilation, and the filler cap may be altered or replaced. Valve or rocker covers may be substituted, provided that the replacement cover affords no additional function than that of the original stock cover.

6. The crankshaft and main bearing caps may be treated with salt-bath nitriding cover under SAE specification AMS 2755A (tuftriding, etc.)

7. Any oil or lubricants may be used.

8. Water pump, fan, and generator/alternator pulley(s) are unrestricted.

9. Exhaust Outlets

A. It is recommended that all exhaust outlets be no longer than 60cm (23.60”) behind the centerline of the rear axle and positioned between 30cm (11.8”) and 60cm (23.6”) from the ground.

B. For cars unable to comply with the above rule (A.), they shall have a support bracket that attaches within six (6) inches of the outlet end, and the support bracket shall extend no more than thirty (30) degrees from vertical to the rear.

Cortina Engine

All of section Kent Engine applies to the Cortina engine except as specified in this section. Components shall not be interchanged between the Kent and Cortina versions of the engine unless specifically authorized.

a. Compression Ratio

Maximum compression ratio: 10.0 to 1. The following specifications are used in determining compression ratio:

1.64cc - top ring to top of piston

5.60cc - head gasket.

Minimum unswept volume per cylinder:

44.4cc (original engine with standard pistons)

45.1cc (original engine with .030” o/s pistons)

b. Block

Use of a Ford engine block ( Cortina ) is required. The 1600 Pinto block, P/N DIFZ-6010-C, may be used as a replacement for the Cortina block; Standard Pinto tappets, P/N DORY 6500A and DIFZ 6500A may also be used when this block is used as a Cortina replacement.

c. Cylinder head

Ports may be reshaped by the removal of metal as long as the port diameter at the manifold face of the head does not exceed the following dimensions:

Inlet: 1.50” Exhaust: 1.16”

Combustion chamber:

Minimum depth 0.115”

Maximum length: 3.15”

Minimum volume per cylinder: 7.8cc

Reshaping is prohibited.

Ford Pinto cylinder head P/N DORY 6049B is permitted.

d. Inlet Manifold

Use of Ford inlet manifold 681-6015D-A, 691F-9425-AA, 691F-9425-AB, 2737E-

8425-B, 701F-9425-EA (Cortina) is required.

The ports may be reshaped by the removal of metal as long as the following dimensions are maintained:

Maximum size at head face:

Cyl. 1 & 4: 1.48” x 1.28”

Cyl. 2 & 3: .25”

Maximum size at carburetor flange: 3.060” x 1.389”

Maximum width: 3.80”

Primary choke end radius: .709”

Secondary choke end radius: .787”

e. Pistons

Standard, 0.015 inch oversize or 0.030 inch oversize pistons may be used.

Piston Maximum diameter:

Standard: 3.189"

0.015” o/s: 3.204"

0.030” o/s: 3.219"

Depth of bowl: 0.500" +/-.005"

Minimum volume of bowl: 31.5cc

Maximum diameter of bowl: 2.28"

Centerline of wrist pin to crown: 1.737" +/-.002"

Overall height: 3.30"

Minimum weight

w/rings & pin: 485 grams

Weight of pin: 115 +/- 2 grams

Wrist Pins are unrestricted provided that no modification is made to the piston for the installation of the wrist pins.

f. Valves

Distance apart at centers: 1.540” +/- .020”

Max. diameter:

Inlet: 1.502”

Exhaust: 1.252”

Overall length:

Inlet: 4.280" +/- .006"

Exhaust: 4.260" +/- .006"

g. Crankshaft

Weight: 23 lbs. 8 oz. minimum

The crankshaft from the Kent engine may be used.

h. Carburetor

Weber 32 DFM or DFD or Holley 5200

Venturi Diameter:

Primary: 26mm

Secondary: 27mm